When you first learn about 3D printed parts, it’s hard to imagine what they can do for you and your company. Even we assumed we would print a few things and then stow the printers away in the closet, gathering dust over the years. We were wrong.

Extremely wrong.

But is it Useful?

The obvious candidates for 3D printing are any parts used internally to the company, such as machining fixtures, assembly aids, and test jigs. The second tier are parts used inside of products where blemishes are inconsequential, such as wire routing gadgets and component mounts. The third tier are panels on the back of the unit where a perfect finish is not required.

For industrial equipment manufacturers, the fourth tier of 3D printing extends to virtually any bracket or panel. As these machines often use roughly finished aluminum parts for such things, the 3D printed parts are often better in appearance (and more cost effective).

For uses where the part is to be visible in a commercial quality product, the parts must usually be sanded and painted. The time to print combined with finishing time can make this usage less economical than other methods, especially in large quantities.

Some of the best printers can produce a finish suitable for lower-end commercial products. However, even these can end up with a blemish somewhere on each part. A hiccup on one layer will cause a ripple for several layers above. In addition, holes or text in the part usually cause unattractive ripples all the way to the edge of the part due to the manner in which the extruder paths are calculated.

Yet, we still find ourselves saying, at least three times a week, “Let’s 3D print a gizmo to hold this gizmo at this angle”. One amusing use (from an engineer’s point of view) is the replacement of a super hard to machine high-temperature material in a precision device. We had documented the part in our cad program with the intention of having it machined, but someone printed it in InnoPet just for giggles (we need all the giggles we can get). Since it was easy to shape and tweak, it ended up on the machine. And it’s still there, less than an inch away from a small electrical arc immersed in heated oil. The steel an inch away becomes too hot to touch, but the part shows no sign of melting. Since it only cost a few bucks to print, we just throw a few spares in the toolkit in case of catastrophic events (which eventually proved themselves useful once the original part inevitably caught fire).

It’s the Little Things

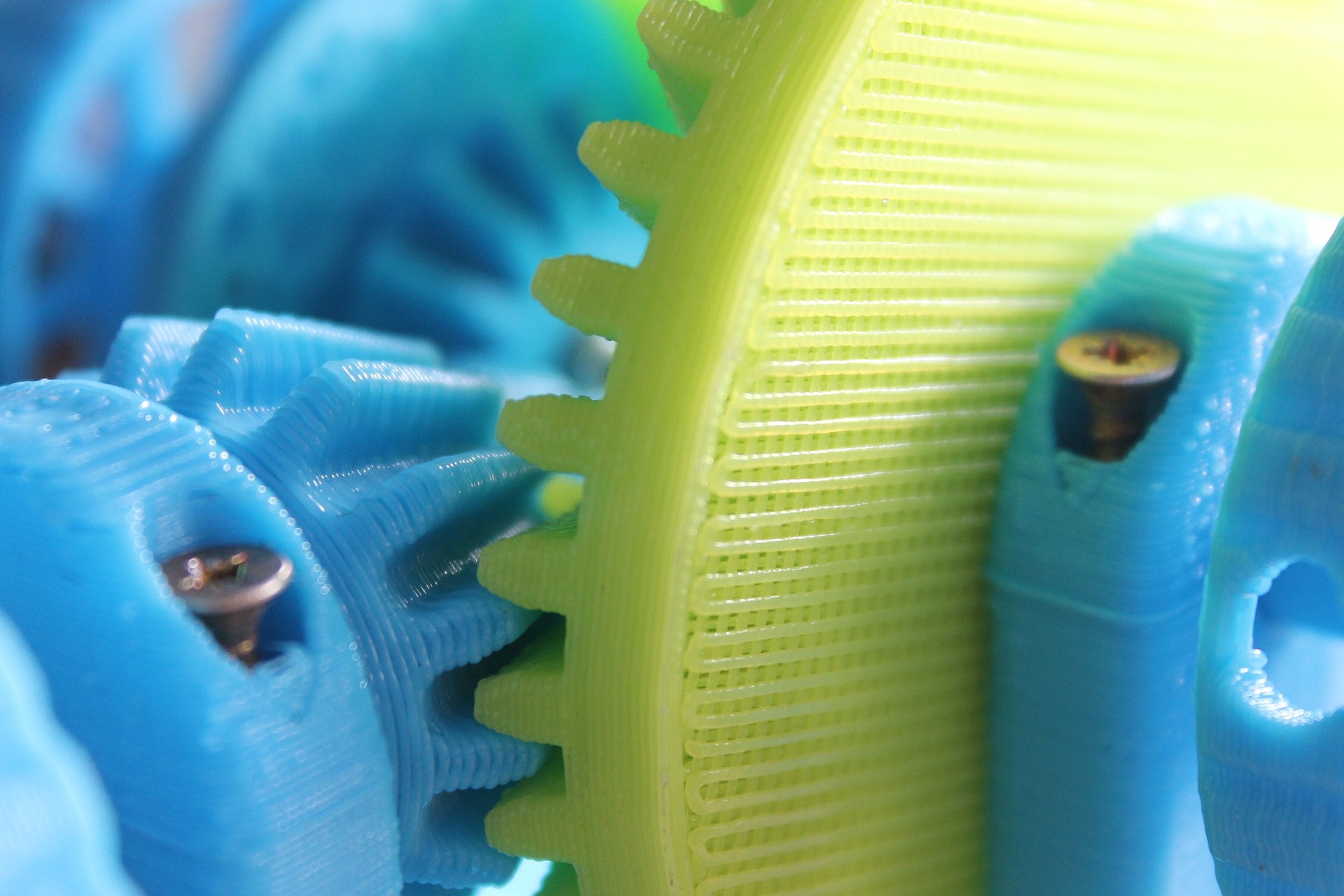

There are small tricks which make a big difference in the usefulness of 3D printed parts. One of these is Brass Thread Inserts for plastic. These allow a screw to be used to form a strong connection… and they look great too!

Another benefit is text printed right on the parts…other kinds of labels are difficult to apply and become easily destroyed. Printing the label right on the part kills two birds with one filament. The text must be fairly large, at least 0.2” high, but it will never wear out in most use cases. Clients usually ask us to print their name, the part number, and label connectors with a name or number.

After one of our customers put some branded parts in the field, one observer noted that they must be getting really big to have custom made plastic parts. Of course he thought they were using injection molding technology, and no one disabused him of the notion.

Conclusion

3D printed parts are already being used in the industrial field, and with great success. Some of our clients manufacture large industrial systems, each of which currently uses 20 to 30 (sometimes even more) 3D printed parts… in about 7 or 8 different forms.

It’s probably worth thinking about how 3D printed parts can lower your costs and increase efficiency.